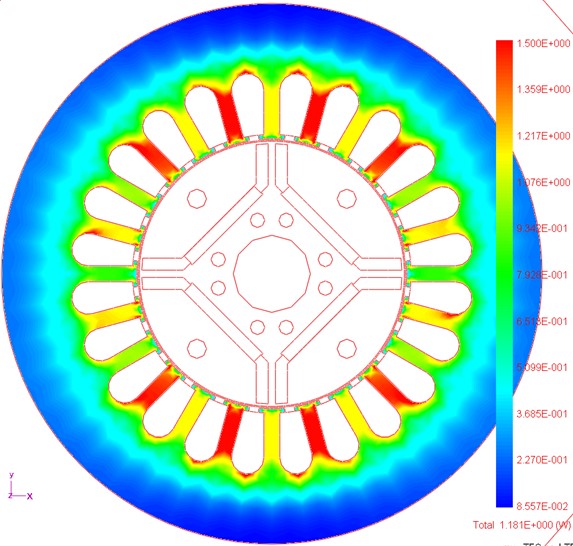

Iron loss evaluation that is becoming a bottleneck in motor analysis In the conventional method, the iron loss is a function of only the magnetic flux density, so it was not accurate, but the magnetic field and the magnetic flux density are accurately obtained and the iron loss is calculated as "vector magnetic characteristics Analysis ". High accuracy magnetic field, magnetic flux density, iron loss distribution which can not be realized by other software can be calculated.

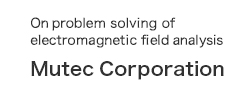

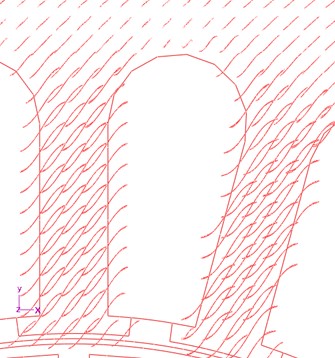

- Magnetic vectors can be calculated with high accuracy by considering vector magnetic characteristics.

- The rotating magnetic field and hysteresis can be calculated.

- It is finished as an easy-to-use iron loss evaluation tool.

- A permanent magnet excitation function and torque calculation function are also implemented.

Vector Magnetic Property Technology Laboratory website (external site)

Example of μ-E&S analysis

|

|

|

| Hysteresis curve display | Rotating magnetic field (magnetic flux) Lissajous waveform | Loss distribution contour display |

What is the E&S model?

The E & S model is a mechanism for analyzing considering the vector magnetic characteristics, invented by Professor Enokizono Oita University et al. The main feature is that the results of precise measurement of magnetic flux density and magnetic field intensity are stored in a database and are referred to in analysis. Because analysis is carried out based on actual measurement results, more reliable analysis results are obtained.

The idea as the basis of the E&S model "vector magnetic characteristics"

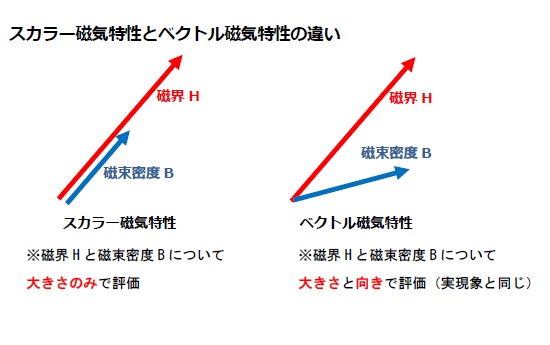

| Vector magnetic properties are magnetic properties that take into account the relationship between the magnetic field H and the magnetic flux density B of the electromagnetic steel material up to the direction (vector). The conventional analysis method is called "scalar magnetic characteristic", and the directionality of the magnetic field H and magnetic flux density B is not taken into consideration (calculation is made assuming that the magnetic field H and the magnetic flux density B are in the same direction) . However, when considering actual phenomena, the magnetic field H and the magnetic flux density B are mostly oriented in different directions. In other words, it can be said that the vector magnetic characteristic is a model conforming to the real phenomenon. This tendency becomes more noticeable as the magnetic flux density becomes higher. Conversely, in the case of low magnetic flux density, good analysis results were obtained even with "scalar magnetic properties". However, since the magnetic flux density will be high in considering efficiency and miniaturization of electromagnetic equipment in future, "vector magnetic characteristics" must be taken into consideration. |

|

|---|

What can be done by considering vector magnetic characteristics

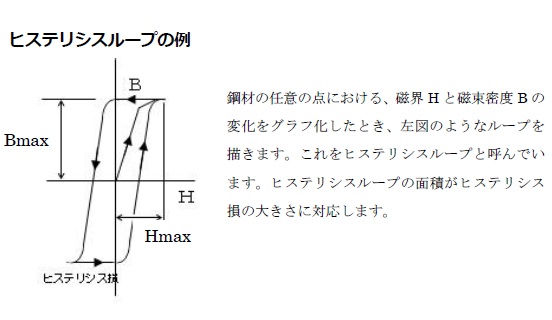

| By considering the vector magnetic characteristics, it becomes possible to see the rotating magnetic field and the hysteresis phenomenon (the correlation between the magnetic field H in the magnetic material and the magnetic flux density B) which could not be seen with the scalar magnetic characteristics. Especially hysteresis phenomenon is one of causes of loss (loss due to hysteresis phenomenon is called hysteresis loss), and it can be said that it is a great merit in the loss evaluation of steel material to be accurately obtained. Also, the hysteresis loop forms different shapes depending on the location of the steel material. Since the shape is different, the area is also different, so the magnitude of the hysteresis loss will be different. In other words, the magnitude of the loss occurring at each part of the steel material is different. |

|

|---|

Possibility of E&S Next-generation iron loss evaluation method

From the viewpoint of effective use of energy, efficient use of electric energy is required. It is said that 50% of the total power generation is electric power use by the motor, and efficiency of the motor is a very big issue.

When considering further efficiency improvement, there is a limit in the evaluation by the conventional method. We need to conduct more detailed evaluation and link to design.

I think that analysis by E & S model has a big meaning in such a situation.